Automotive applications come in a variety of different use cases and requires innovative technology from manufacturers to keep up with their growing demand. Find the ideal solution for your vehicle in our specialized range of automotive actuators.

Linear Motion for Powersports

Durable and innovative technology to keep up with growing demands.

2.41%

Average YoY Cost Reduction99.8%

Perfect QC Pass Rate100%

Powered By Renewable EnergyWe're More than a Supplier: Adding Value Beyond the Product.

With an unwavering commitment to mutual success, we're a flexible partner that adds value at every step along the component lifecycle.

Consistently High Product Quality

Get ultra-low product failure rates with a quality control regime that's reliable, stringent, adaptive and systematic.

Progressive Automations is ISO9001.2015 Certified

Get quality you can trust. Work with a partner that's truly committed to continuous improvement.

Flexible Pricing with Pass-Through Cost Reductions

Unlock savings with ramp-up friendly, inflation-resistant pricing, where scale-related savings pass directly on to you.

We Deliver on Time, Every Time.

Even with supply chain challenges becoming more common, we've maintained a 98% on-time shipment rate since 2017.

Zero Lead Times & Unparalleled Flexibility with Smart Logistics

Avoid costly air freight and production delays. We get custom units to your dock in days, not months.

Electric linear actuators revolutionize UTVs and ATVs by enabling precise control of loading mechanisms and movement. They enhance safety with advanced automation, reducing manual labor and improving productivity in various challenging environments.

Golf Carts aThese actuators provide precise control over various mechanisms like steering, braking, and cargo handling. This automation streamlines operations, ensuring consistent and efficient performance. Additionally, by reducing the need for manual intervention, electric linear actuators enhance safety and boost overall productivity.

Actuators drive the precise control over crucial snowmobile components like suspension, steering, and throttle. This automation streamlines operation, leading to a smoother and more efficient ride. Additionally, by reducing the need for manual adjustments, electric linear actuators enhance both performance and rider comfort in demanding winter conditions.

Amphibious Vehicles actuators manage crucial functions like land-to-water transition mechanisms, movement control, and integration with automated systems. This streamlines operation, ensures consistent performance, and reduces the need for manual adjustments, enhancing both productivity and safety.

“There was nothing in the way of a camper that went on like a Tacoma, a Chevy Colorado, a Nissan Frontier, a Ford Ranger,” Wise said. “Anything that was available had the cantilevered bed that went over the top of it, and it was canvas. So, we came up with a hard-sided, folding camper. It’s all fiberglass and aluminum. It’s completely waterproof and it comes in at less than 1,200 pounds."

Rick Wise and Joe Orr

Co-founders of Cube Series

Custom Linear Motion for Powersports

Actuator Customization

Transform your projects with actuators built for your unique challenges. Whether you're transitioning from hydraulics or facing issues like water ingress, we understand that every application is unique.

Our engineers help you craft solutions that fit your exact specifications, with flexible minimum quantities, turning complex requirements into precise, efficient designs.

As your needs evolve, so do our solutions - we're here for the long haul, and you're gaining a partner dedicated to your success.

Case Studies

Make The Project Of Your Dream

Cube Series Camper

By using linear actuators and ultra-lightweight folding technology, Cube Series RV aims to offer lightweight, compact, and convenient campers that are also suitable for compact pickups without sacrificing durability. In this case study, we will cover the process, challenges, and solutions the team at Cube Series RV had faced in bringing their Cube Series Camper to life.

Make The Project Of Your Dream

Boat Engine Hatch

By using quality custom linear actuators and advanced control systems for synchronization, Progressive Automations offers convenient, reliable, and user-friendly automation solutions that enable customers to protect their engine hatches through automated hatch covers. In this case study, we will cover the process, challenges, and solutions involved in bringing automated hatch covers to life for boats, yachts, and other sea vessels.

DISCOVER MORE

Blog Post

Download The Testing Guide

This guide will outline essential steps and the process of evaluating a sample actuator. We include a checklist to ensure all the requirements are met.

Blog Post

Top 10 Questions We Get from Our OEM Customers

You will find useful FAQ from OEM Customer as for your search for a parts supplier of electric linear actuators.

Application

UTV & ATV

Electric linear actuators revolutionize UTVs and ATVs by enabling precise control of loading mechanisms and movement.

Challenges

UTV/ATV electric actuators face harsh environments, vibrations, fluctuating power, high loads, including extreme temperatures, dust, and water and require frequent maintenance.

All while providing precise control, making durability and reliability essential for UTV/ATV electric actuators in off-road and industrial settings.

Solutions

Sealing protects electric actuators in UTVs/ATVs from tough environments. Reinforced structures and voltage regulation address vibration and power fluctuations.

High-capacity actuators with precision control can handle heavy loads while maintaining smooth movement. Additionally, durable components reduce maintenance needs and extend actuator lifespan.

Benefits

Electric linear actuators excel with precise positioning, reliability from brushless motors and high IP ratings, energy efficiency via regenerative braking, easy installation, safety features, environmental benefits, and versatile applications in UTVs and ATVs.

Improve productivity in tough environments like off-road terrain, agriculture, and industrial settings.

Upgrade your UTV or ATV with electric actuators to experience enhanced performance and reliability.

UTV & ATV

Adjusting Cargo Beds

Model

PA-17 Linear Actuator

Function

Electric actuators adjust the tilting mechanism of cargo beds.

Benefits

Provides smooth and precise control over the angle of the cargo bed, facilitating easy unloading of materials. Enhanced reliability and reduced maintenance needs compared to hydraulic systems ensure consistent performance.

PA-17 Linear Actuator

The PA-17 Heavy Duty Linear Actuator offers high force ratings and durable construction at an excellent price point.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP65 Water Protection

- Excellent Price/Performance Ratio

Request Custom Specs

Application

Golf Carts

Electric linear actuators are transforming golf cart industry by automating key functions such as steering, braking, cargo handling, and other critical components.

Challenges

Golf cart electric actuators face challenges in affordability and electrical power efficiency to optimize battery life. Environmental factors such as weather conditions and exposure to dust needs to be considered.

Weight is a critical factor that impacts both performance and efficiency. A heavier golf cart requires more energy to operate, leading to faster battery depletion and increased wear on components like tires and motors.

Solutions

To overcome these challenges, golf cart electric actuators can be designed with energy-saving features, robust weatherproofing, high-precision feedback systems, light weight durable materials, and noise-reduction technologies.

Standardized communication protocols and safety features like overload protection ensure seamless integration and safe operation. Additionally, modular designs and cost-optimized manufacturing address adaptability and affordability.

Benefits

Electric linear actuators elevate golf carts by offering precise control, smooth operation, energy efficient operation, and low maintenance requirements.

These actuators are compact, customizable, and designed for low maintenance, making them perfect for golf cart applications where reliability and efficiency are paramount.

Furthermore, the use of electric actuators contributes to a greener environment by minimizing noise and reducing emissions compared to traditional mechanical systems.

Golf Carts

Navigation Enhancements

Model

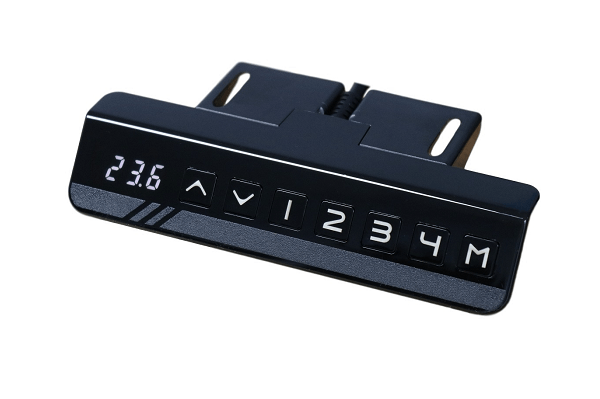

PA-04 Linear Actuator

Function

Assists in advanced steering mechanisms and navigation systems

Benefits

Improves steering precision and control, making the golf cart easier to maneuver. Can be integrated with automated systems for enhanced navigation and obstacle avoidance, increasing safety.

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up with a balance of water resistance and performance-to-price ratio. It is popular in various industries, including the automotive sector.

Key Features

- Versatile Force Rating

- Low Noise

- High Speed

- Maintenance Free

- Excellent Price/Performance Ratio

- IP66 Water Protection

Request Custom Specs

Application

Snowmobiles

Actuators provide precise control over key snowmobile components, including suspension systems, steering mechanisms, and throttle control.

Challenges

Snowmobiles face extreme conditions that present several challenges for electric actuators. Cold weather can cause material brittleness and reduce battery efficiency.

Exposure to snow, ice, salt, and water can result in moisture buildup, which may lead to corrosion and other performance issues.

Snowmobiles also navigate rough terrains, introducing significant vibrations and shock loads that actuators must withstand.

Integration with existing vehicle systems, handling varying load capacities, and compliance with environmental regulations are other factors manufacturers need to address—all while keeping costs competitive.

Solutions

Snowmobile actuators require robust solutions to overcome these challenges. Implementing cold-resistant and corrosion-resistant materials ensures durability in freezing temperatures and moist environments.

Actuators with high IP ratings offer moisture protection, while shock-absorbing designs withstand vibrations on rugged terrain.

Additionally, energy-efficient features and standardized controls improve actuator performance, enabling better integration with snowmobile systems.

By choosing eco-friendly materials and optimizing load capacities, manufacturers can meet environmental regulations and maintain cost-effectiveness.

Benefits

Electric linear actuators in snowmobiles offer precise control over suspension, steering, and throttle, improving performance and comfort.

They ensure reliable operation in harsh winter conditions with cold-resistant, corrosion-proof designs.

Additionally, they are energy-efficient, low maintenance, and seamlessly integrate with snowmobile systems for enhanced safety and durability.

Snowmobiles

Tention Track

Model

PA-17 Linear Actuator

Function

Electric linear actuators are used to adjust the tension of the snowmobile track.

Benefits

Allows for optimal track performance based on snow conditions and terrain, ensuring efficient traction and maneuverability.

PA-17 Linear Actuator

The PA-17 Heavy Duty Linear Actuator offers high force ratings and durable construction at an excellent price point.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP65 Water Protection

- Excellent Price/Performance Ratio

Request Custom Specs

Application

Amphibious Vehicles

Actuators streamline operations, ensure consistent performance, and significantly reduce the need for manual adjustments.

Challenges

Amphibian actuators face significant challenges such as exposure to moisture, salt water, and extreme temperatures. These conditions require robust design features to ensure reliable performance.

Specific requirements for these actuators include a high load capacity, power efficiency, and seamless control system integration.

Additionally, vibration resistance is crucial for maintaining functionality in rough terrain, while low maintenance needs reduce downtime and operational costs.

Fast response times are essential for dynamic environments, and effective noise reduction technologies are necessary to provide a comfortable user experience.

Solutions

Amphibian actuator solutions utilize resistant materials and seals to endure harsh environments, protecting against moisture and salt water.

High-capacity actuators effectively handle heavy loads, while power-efficient designs optimize energy use. Standardized control systems ensure seamless integration.

Robust designs reduce vibration and maintenance needs, and quiet operation is achieved through innovative design and control strategies.

Benefits

Electric linear actuators elevate amphibious vehicles by offering precise control for land-water transitions, reliability in harsh environments, low maintenance needs, and energy efficiency.

Their compact design, quiet operation, and easy system integration enhance functionality, while safety features ensure secure operations.

Amphibious Vehicles

Wheel & Track Retraction/Extension

Model

PA-17 Linear Actuator

Function

Actuators retract and extend wheels or tracks for land and water operation.

Benefits

Seamless and precise transitions between modes allow efficient operation in both environments, improving the vehicle's versatility and reducing manual intervention.

PA-17 Linear Actuator

The PA-17 Heavy Duty Linear Actuator offers high force ratings and durable construction at an excellent price point.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP65 Water Protection

- Excellent Price/Performance Ratio